The use of plastic or polymers instead of metal has been increasing steady over the past decade. With the inventions of new plastics every year, this rate will further increase. Plastics are lightweight, quick to manufacture, cost effective compared to metals. The strength of plastic has been a limitation but with new high performance materials and design, this limitation can be overcome. In this article, we will be sharing different types of plastic manufacturing process and will help you decide which one to choose based on your specific application.

BLOW MOLDING

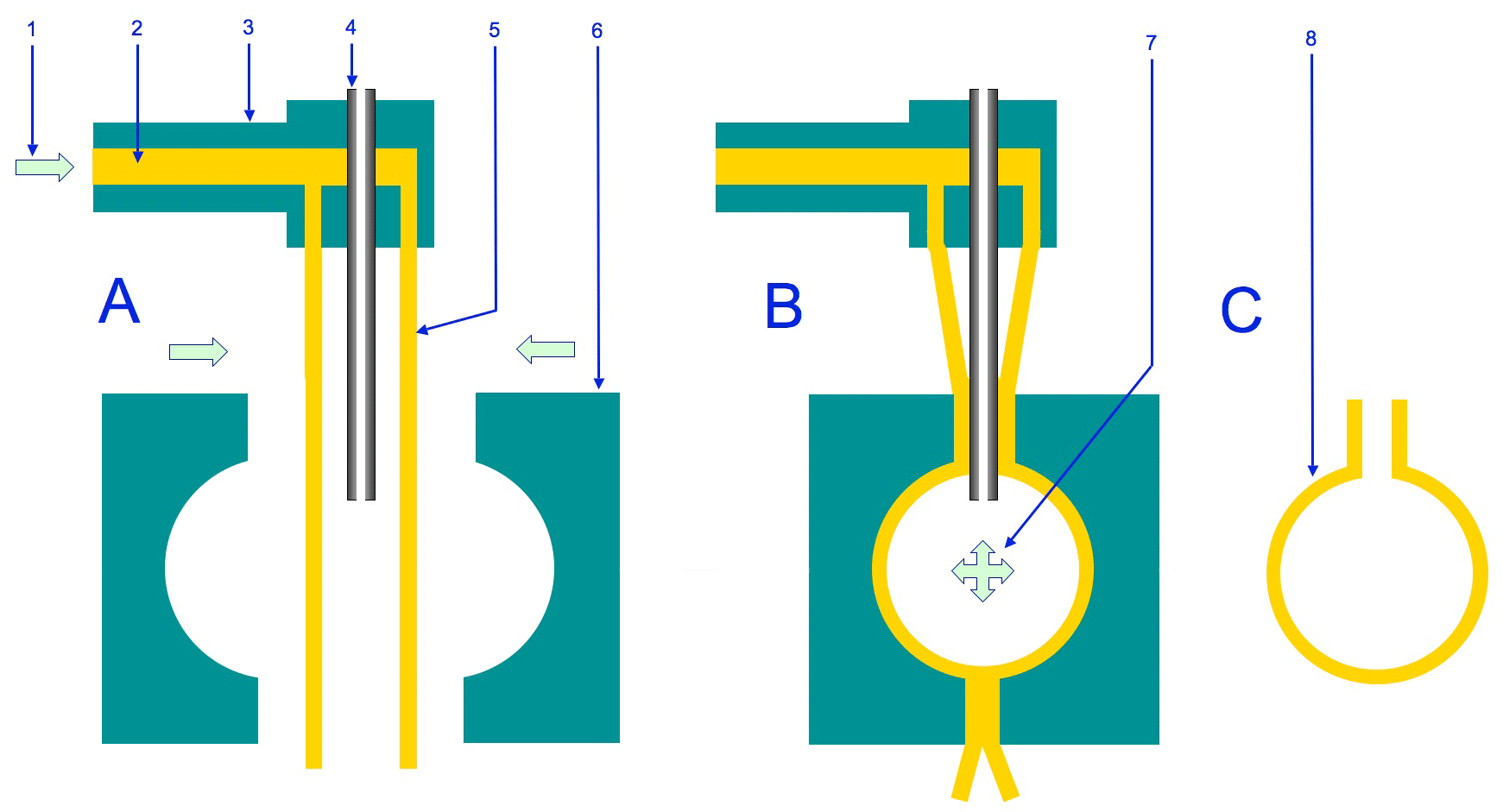

Blow molding is used for hollow parts. A hollow tube with one closed end called parison is extruded or injected in the mold cavity and then expanded with the help of pressurized air. Depending on how the parison is formed, blow molding is classified into 2 types.

- Extrusion Blow Molding: In this method, the parison is first extruded then the mold closes on the parison closing one of its ends. Then pressurized air is blown into the parison to inflate it up to the mold surface. Mold is generally at room temperature which helps in solidifying the plastic.

Figure 3: Extrusion Blow Molding

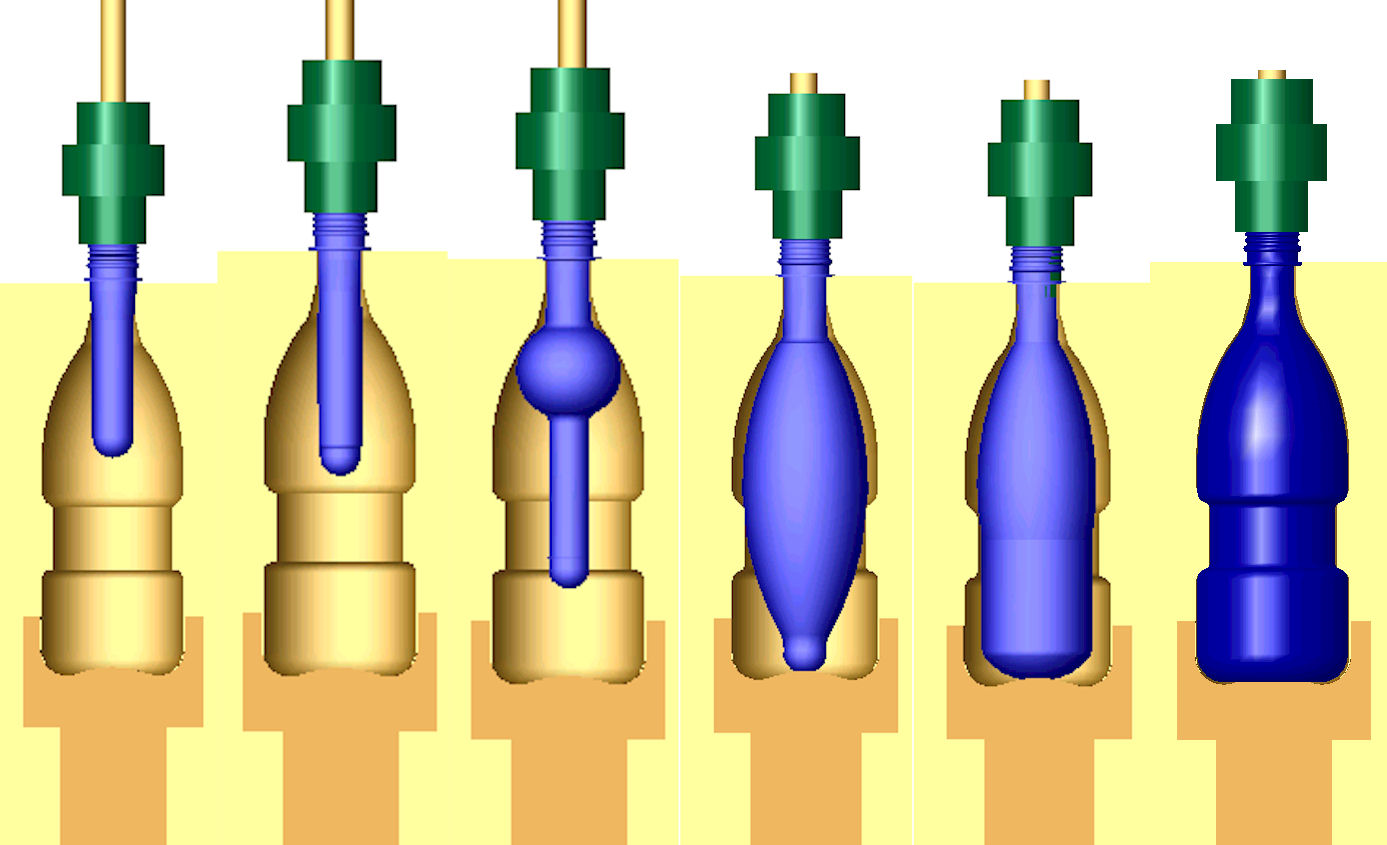

- Injection Blow Molding: In this process, the parison is injected into the core pin then the core pin rotates and goes inside the mold. After that, the parison is inflated by using pressurized air and it fills the mold cavity.

Figure 4: Injection Blow Molding

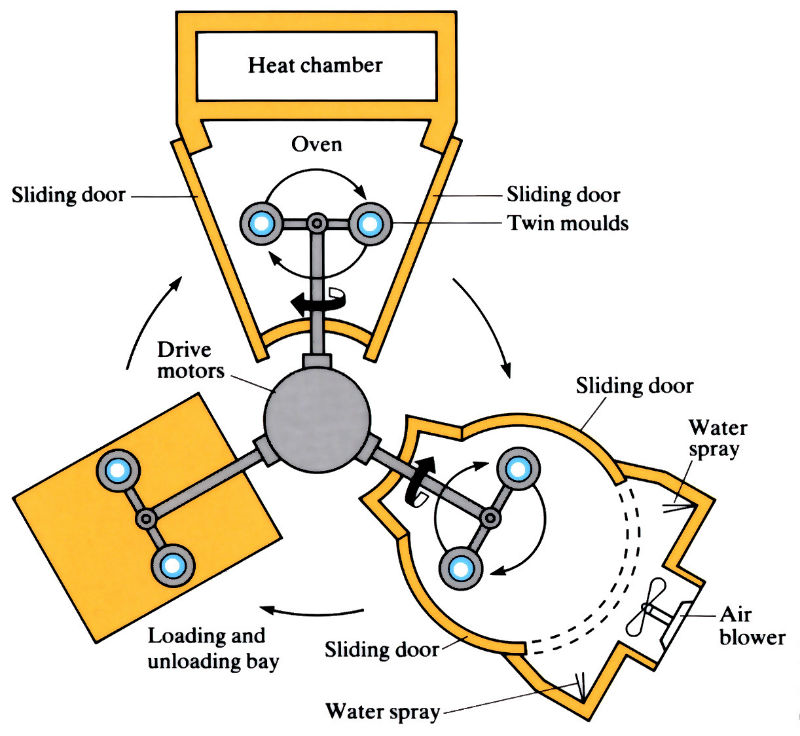

ROTATIONAL MOLDING

Rotational molding is another process that is used for manufacturing hollow parts. The process is simple but the set-up is complicated. The plastic is poured into the mold in powder form. Then the mold is closed and rotated at slow speed in the heating chamber. The plastic melts due to the heat and starts flowing. The mold generally rotates in bidirection to ensure uniform wall thickness. After that, the mold is cooled in the cooling chamber. Cooling can be achieved by air cooling or mist spray or a combination of both. Keep in mind that the mold keeps rotating until the time of ejection. Although any thickness can be achieved by rotational molding, higher wall thickness means more material and cycle time. The cost of mold for rotational molding is less compared to injection molding & blow molding due to its simplicity. This process is generally used for large tanks, or hollow parts having complicated shapes.

Figure 5: Rotational Molding (Courtesy: Open.edu)

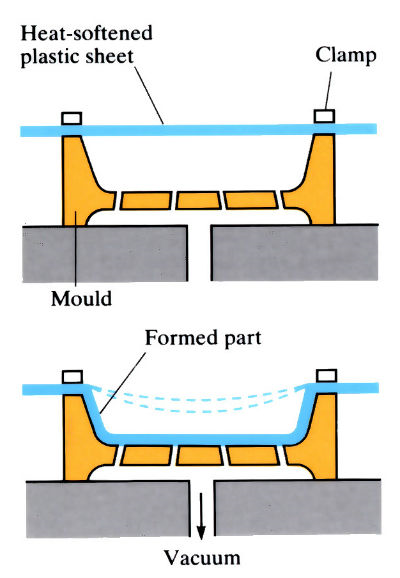

THERMOFORMING

Thermoforming is similar to the hot forging of metal. A plastic sheet of desired thickness is heated to a pliable state on top of the mold then formed into the mold cavity. Depending on the technique of forming it is divided into 2 types.

Thermoforming is suitable for parts that are simple and can be manufactured by a single core or cavity mold. Also, the part should have a uniform wall thickness. Thermoforming is generally used for packaging, cups, etc. The main advantage of thermoforming is the material of mold. Molds for thermoforming can be made of POP, Wooden, Aluminum, etc. which are easily available and less expensive.

MACHINING

Plastic parts can be produced easily with molding processes but if the quantity is very small and plastic is rigid it can be made into the required shape using machining. Machining of plastic process is similar to that of metal but the parameters such as cutting speed, feed rate, depth of cut, etc. vary depending on different plastic. Machining can also be used as post-processing after molding. Sometimes it is easier and economical to add features on to the molded part rather than incorporating it into the mold.

Figure 7: Machined Plastic Components

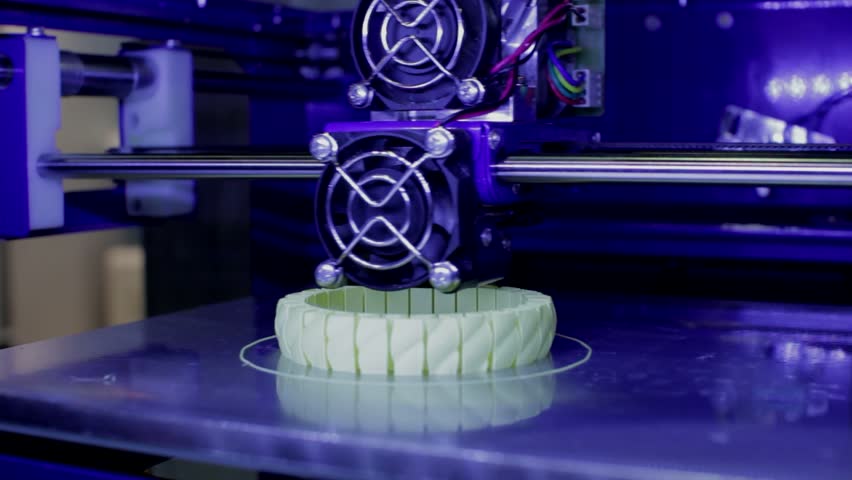

3D PRINTING

3D printing can make complex shapes direct from CAD or Scanned model without mold. Materials that can be 3D printed are limited, but for prototyping, it has become an effective technology. Parts are made layer by layer in 3D printing, so the time required mainly depends on the size of the part, layer height, speed of printing, infill shape and density. 3D Printing has seen good growth in recent times and is slowly catching up as alternate means for producing plastic parts. There are still some issues such as poor surface finish specially below supports, cycle time, part strength, post processing methods that are being improved to make this technology more mainstream. Below are few of the 3D printing technologies for plastic.

One of the major advantages of 3D printing is that is can be used without any additional preparations such as mold manufacturing, or sheet manufacturing in case of thermoforming.

The manufacturing method plays a very big role in the cost of the part being manufactured. Selecting the method for manufacturing affects the design of parts as well. Injection molding is an expensive process and can be used for mass production only. Blow molding and rotational molding are used for hollow parts only. If the quantity is low, other alternatives such as thermoforming machining, or 3D printing can be considered. Thermoforming can be used for simple parts only so the design should be as simple as possible for thermoforming. For more complex parts with many undercuts, one of the 3D printing technologies can be used depending on the application of part. Machining is suitable for making small modifications in molded parts and also it can be used as a complete manufacturing method for hard plastics such as Delrin, Nylon, PEEK, etc. At Improvians, we can help you will all your plastic design and manufacturing requirements.